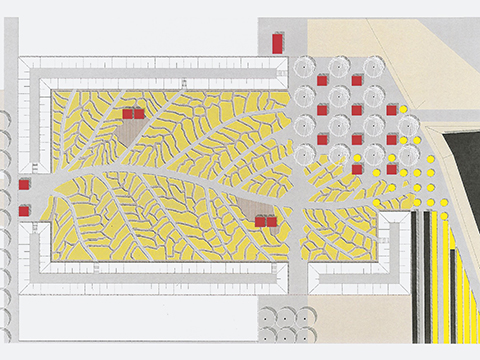

Prefabrication was the answer to a challenging task at the Federal Garden Exhibition 2005 (commonly referred to as BUGA) in Munich for a temporary seasonal planting display area. "The Leaf Garden" consisted of planting beds with paths following the complex pattern of leaf nerves. As the structure was temporary the client requested a low-cost solution without compromising the design. We chose untreated steel and wood as the material for the edges of the planting beds for easy recycling and cost considerations. This reduced the available construction time to only 10 days after the end of the winter to get ready for the first planting in April.

As a member of the design team of Rainer Schmidt Landscape Architects Munich, I developed a system based only on two elements: notched pinewood boards and angled steel plates as connectors only assembled with 2 screws. Each board got a unique identifier. I extracted the line's identifier and geometry data from AutoCAD with some lisp code and AutoCAD's data extraction tools into MS Excel. In MS Excel, we could derive the angles between the lines for the connectors and assigned a unique identifier to each connector. The length of the boards than got adjusted to fit with the connectors properly.

After we created a complete list with all boards and angles we pushed the ordered data from Excel with macros back to AutoCAD to control visually that the list is complete and correct.

Boards and connectors were prefabricated over the winter and packed in the assembly order. We tested by assembling a part indoor.